Target markets such as Europe, the United States, and the Middle East each have specific packaging requirements. Western buyers demand strict adherence to hygiene standards, clear product information, and transparent packaging. In the Middle East, considerations like halal certification, attractive design, and size matter. Therefore, in the export packaging dried fruits Iran process, you must first understand each market’s needs, then balance technical, economic, and marketing criteria when selecting packaging materials

Target markets such as Europe, the United States, and the Middle East each have specific packaging requirements. Western buyers demand strict adherence to hygiene standards, clear product information, and transparent packaging. In the Middle East, considerations like halal certification, attractive design, and size matter. Therefore, in the export packaging dried fruits Iran process, you must first understand each market’s needs, then balance technical, economic, and marketing criteria when selecting packaging materials

For purchasing the highest quality Iranian pistachios, contact our experts

Key Criteria for Export Packaging of Dried Fruits

Selecting Suitable Packaging Materials

Vacuum-Sealed Bags

Vacuum-Sealed Bags- Advantages: Removing air from inside the package prevents oxidation of the oils in dried fruits (e.g., pistachios and almonds), extending shelf life by several months.

- Disadvantages: Vacuum sealing equipment can be expensive; if production costs rise significantly, the final product price may become less competitive.

- Polypropylene (BOPP/CPP) Bags

- Advantages: High transparency, flexibility in various sizes, and direct printing of logos or product information.

- Disadvantages: Lower shelf life compared to vacuum packaging; unless a moisture-barrier layer is added, humidity can still permeate.

For purchasing the highest quality Iranian almonds, contact our experts.

- Cardboard Boxes (Laminated Carton Boxes)

- Advantages: Premium appearance, ability to incorporate multilayer structures with inner plastic or aluminum coatings for enhanced protection.

- Disadvantages: Heavier weight compared to plastic bags; shipping costs and handling become more expensive.

Practical Example: A company exporting green pistachios to Europe often uses a combination of vacuum-sealed packs for the product’s interior and laminated cardboard boxes for outer protection and aesthetics. This approach preserves freshness while delivering an eye-catching presentation.

A company exporting green pistachios to Europe often uses a combination of vacuum-sealed packs for the product’s interior and laminated cardboard boxes for outer protection and aesthetics. This approach preserves freshness while delivering an eye-catching presentation.

International Standards (FDA, ISO, and Other Certifications)

- ISO 22000 (Food Safety Management System):

The packaging manufacturer must demonstrate compliance with food safety protocols at every production stage (from raw material acceptance to final packaging). Without this certification, many European and American importers will delay or reject shipment acceptance. - FDA Regulations (For U.S. Exports):

In addition to microbial and quality testing of the dried fruit itself, packaging materials (films, foils) must meet FDA-approved food contact material standards. Any non-compliant materials risk shipment refusal at U.S. ports.

For purchasing the highest quality Iranian hazelnuts, contact our experts.

- Halal Certification and Export Documentation:

For Middle Eastern markets, dried fruit packaging must bear a Halal certification (especially if additives are involved) and may require a Certificate of Origin and phytosanitary certificates indicating country of origin directly on the packaging.

Note: In the export packaging dried fruits Iran workflow, consult with Iranian certifying bodies (Institute of Standards & Industrial Research of Iran, Chamber of Commerce, and Iran Food and Drug Administration) before finalizing the packaging line to confirm required documentation and standards for your target market.

In the export packaging dried fruits Iran workflow, consult with Iranian certifying bodies (Institute of Standards & Industrial Research of Iran, Chamber of Commerce, and Iran Food and Drug Administration) before finalizing the packaging line to confirm required documentation and standards for your target market.

Resistance to Transportation Conditions (Humidity and Temperature)

- Moisture Barrier Protection:

- Pistachios, almonds, and other nuts are highly sensitive to moisture. If humidity penetrates the package, nuts can become soft or develop mold.

- Inner layers of aluminum foil or multi-layer polyethylene are commonly used to prevent moisture ingress.

- Monitor relative humidity (RH) during sea or air transit; ideally, it should not exceed 50% to maintain nut integrity.

For purchasing the highest quality Iranian walnuts, contact our experts.

- Temperature Tolerance:

- During long-distance shipping, packages may be exposed to varying temperatures—from refrigerated storage to airport holds and warehouse environments. Simple plastic bags might soften under high heat or become brittle in extreme cold.

- Choose packaging materials with a wide operational temperature range (–20 °C to +60 °C) to avoid deformation or breakage.

- For certain routes (e.g., air cargo), thermal liners may be necessary to provide additional temperature insulation.

Practical Advice:

Before placing a bulk packaging order, request sample packages and subject them to simulated stress conditions (temperature cycling and vibration tests). This prevents costly losses due to damaged goods upon arrival.

Introducing Reliable Packaging Suppliers in Iran

Below are two leading Iranian companies specializing in export-ready dried fruit packaging. Each has years of experience and holds the certifications necessary for international trade.

Aria Pack Company

- Core Expertise: Manufacturing various vacuum-sealed and resealable bags for dried fruits, using inner aluminum layers and full-color printing capabilities.

- Key Advantages:

- Custom-printing services for logos and nutritional information.

- Option to include transparent windows for product visibility.

- ISO 9001 (Quality Management) and ISO 22000 (Food Safety) certifications.

- Website & Contact:

- Website: www.ariapack.com

- Sales Department: +98-21-44556677

- Brief Description:

With over ten years of experience, Aria Pack serves both domestic and export markets. For exporters, they offer free samples to test product compatibility, allowing foreign buyers to confirm packaging quality firsthand.

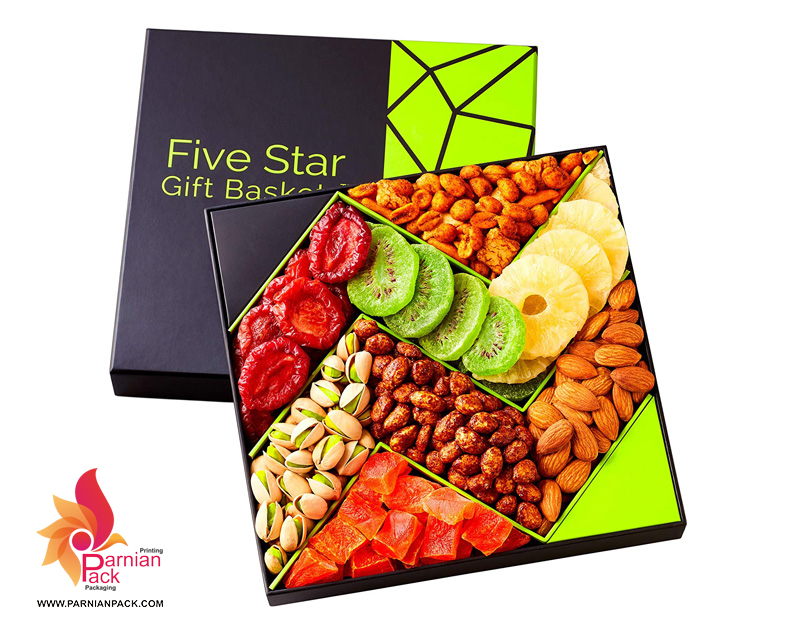

Parnian Pack Company

Parnian Pack Company

- Core Expertise: Designing and producing laminated, moisture-resistant carton boxes for exporting various dried fruits and food items.

- Key Advantages:

- Production of UV-coated, moisture-resistant laminated boxes.

- Equipped with flatbed printing machines for high-quality box designs.

- Holds FDA and HACCP certifications.

- Website & Contact:

- Website: www.parnianpack.com

- Export Department Email: export@parnianpack.com

- Brief Description:

Parnian Pack has executed major projects for leading Iranian dried fruit brands. Their logistics solutions include package design, laboratory testing, and sample shipping to destination countries, streamlining the export process.

Parnian Pack has executed major projects for leading Iranian dried fruit brands. Their logistics solutions include package design, laboratory testing, and sample shipping to destination countries, streamlining the export process.

For purchasing the highest quality Iranian sunflower seeds, contact our experts.

For purchasing the highest quality Iranian pumpkin seeds, contact our experts.

Final Tips and Summary

- Timely Ordering and Minimum Order Quantities (MOQs)

- Before mass production, verify each packaging supplier’s MOQ. Some factories require a minimum order of 5,000 units for vacuum seals or laminated boxes. If your production volume is smaller, per-unit costs may increase or lead times may extend.

- Inspect Samples Before Bulk Production

- Request initial samples and evaluate:

- Color accuracy and logo fidelity.

- Thickness of inner layers (PE, PET, Aluminum).

- Compliance with required certifications (e.g., correct labels, holograms).

- Make adjustments before commencing large-scale production to avoid rework and extra costs.

- Request initial samples and evaluate:

Quality Control and Laboratory Testing

Quality Control and Laboratory Testing- Beyond visual inspection, have your packaging tested in accredited labs for:

- Water Vapor Transmission Rate (WVTR).

- Burst Strength and Puncture Resistance Tests.

- Microbial Safety Tests (immediately after packaging).

- If possible, arrange for an onsite audit by Iran’s standardization authorities to receive final certification approvals.

- Beyond visual inspection, have your packaging tested in accredited labs for:

- Printing Complete Information on Packages

- Alongside an appealing design and high-quality material, ensure the following details are printed on each package:

- Ingredients list.

- Net weight.

- Country of origin (“Product of Iran”).

- Manufacturing and expiration dates.

- Batch or lot numbers.

- Contact details of the exporting company.

- Certification logos (Halal, ISO, etc.).

- Alongside an appealing design and high-quality material, ensure the following details are printed on each package:

- Packaging Costs and Final Pricing

In the export packaging dried fruits Iran workflow, calculate total packaging expenses (materials, printing, machinery costs, taxes, and potential customs duties).

In the export packaging dried fruits Iran workflow, calculate total packaging expenses (materials, printing, machinery costs, taxes, and potential customs duties).- Determine how packaging choices affect your final product price. A premium box might justify a higher retail price, but could also limit initial order size.

- Eco-Friendly Packaging Considerations

- Many European and North American buyers prefer recyclable or compostable packaging. If feasible, select biodegradable materials (e.g., cardboard boxes without plastic lamination or certain bio-plastics) and highlight “Eco-Friendly” on the package and marketing materials.

Conclusion

Conclusion

By following these guidelines—selecting suitable materials, obtaining international certifications, and working with reputable suppliers—you will ensure that your export packaging dried fruits Iran meets both market expectations and regulatory requirements. High-quality packaging not only protects your product but also enhances your brand’s image in the eyes of foreign buyers, increasing the likelihood of repeat orders and long-term partnerships.

Write your comment.